- Interior Systems

- Exterior Systems

- HVAC Distribution Systems

- Air Induction Systems

- Fluid Management Systems

- Flexible Products

Products

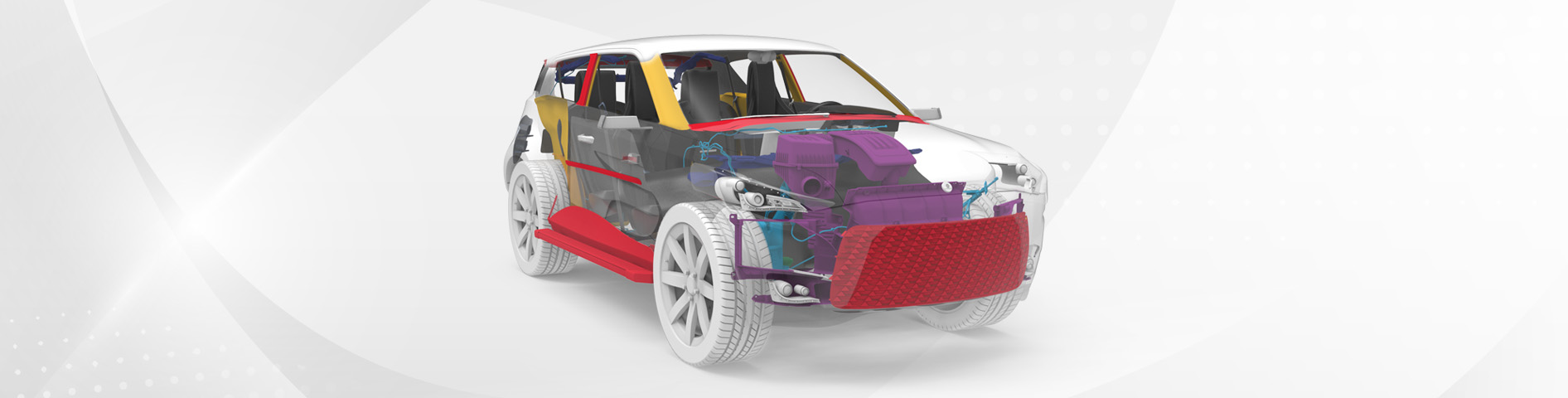

With hundreds of patents on materials technology, products and processing systems, our reputation for product innovation is internationally recognized. Customers use our plastic components and systems, in every area of their vehicles, to pioneer new automotive advancements in performance and sustainability. In addition to the inherent cost savings in tooling, manufacturing and assembly production, ABC Technologies plastic products offer several important functional qualities:

- Light weighting

- Efficient use of space

- Sizing customization

- Vehicle fuel efficiency

- Improved performance, durability and flexibility

- Enhanced permeation and temperature resistance

Interior Systems

Floor Consoles | Cargo Management Systems | Interior Trim | Seat Backs

Load Floor/Deck Boards | Knee/Side | Door Panels

Interior systems accommodate a variety of design and performance features, including impact requirements. Systems are available with Class A finish, featuring molded-in color and/or interior grain match. In addition to manufacturing and assembly, ABC Technologies provides comprehensive design and product development support. Working closely with our customers’ engineering teams, we play an important role in identifying and developing effective product system solutions.

Exterior Systems

Running Boards | Bumper Systems | Body Side Molding | Rocker Panels | Cladding | Cargo Management Systems | Bed Extenders | Roof Ditch Molding

Exterior systems include a variety of components featuring Class A finish, and are available with texture-match and molded-in color. Plastics are playing an increasingly important role in improving overall vehicle design and aesthetic appeal. They can also provide major cost advantages — in design, production and assembly. ABC Technologies’ blow molding and multi-process manufacturing has led to the introduction of many exterior systems and components that were formerly produced using traditional methods and materials. Benefits include improved strength, greater design flexibility, and a reduction in the number and weight of components.

HVAC Distribution Systems

Defroster | I/P | Floor | Auxiliary | Battery Cooling | Brake Cooling Ducts

Air Guides | Aspirator | Module Components

HVAC Distribution Systems showcase ABC’s breadth in moulding and assembly capabilities. Various innovative material options are available to meet customer performance and weight requirements.

Air Induction Systems

Integrated Air Induction Systems | Turbo Ducts | Air Intake Ducts | Resonators

Air Cleaner Housing | Clean/Dirty Air Ducts | Air Box Filters*

Complete systems, including air cleaner housings, air intake ducts, expansion chambers and multiple resonators. Designed to meet performance requirements for air-flow, NVH (Noise, Vibration, Harshness), filtration, temperature and durability. Proprietary technology allows previously separate vehicle systems to be integrated as one, such as air cleaner housing/washer reservoir assembly, for improved system performance and integrity as well as reduced system costs.

Fluid Management Systems

Windshield Washer Reservoir Assemblies | Coolant Overflow Reservoir Assemblies

Surge Tank Assemblies | Power Steering Reservoirs | Battery Trays

Our Fluid Management Team collaborates to create unique fluid management system solutions to maximize limited space and weight reduction. The utilization of our in-house computer-aided engineering capabilities is used to predict, analyze and solve design issues during the design development phase. Rapid prototype services are available to enhance customers’ flexibility and assurance of expectations. In addition, ABC Technologies includes debris reduction systems and conducts leakage testing in our manufacturing process. We provide our clients with optimal packaging techniques for safe and low logistical costs.

Flexible Products

CVJ boots | Rack Pinion Boot | Air Demister Hoses | Prop Shaft Boots

Suspension Dust Covers | Steering Column Covers

Our flexible products are internationally acclaimed for their resistance to fatigue, superior tensile, tear strength and unmatched temperate, chemical and puncture resistance. Our Flexible Products Team continues to move towards size and weight reduction of our flexible products.